Case Dozer Warning Lights can be a significant concern for operators and owners of Case Heavy Machinery. These warning lights are designed to alert users of potential issues with the dozer, ensuring that they maintain machinery in optimal condition while preventing potentially hazardous situations. Understanding the meaning behind these warning lights, recognizing the symptoms, diagnosing problems, and performing appropriate troubleshooting are crucial for any Case dozer operator. Let’s delve deeper into the matter.

Key Takeaways

- Case dozer warning lights indicate various machinery malfunctions, such as hydraulic issues, engine problems, and temperature changes.

- Common symptoms include dashboard warnings, abnormal sounds, and performance issues.

- Possible causes can range from minor faults to significant mechanical failures.

- Regular maintenance is essential to prevent warning light issues.

- Professional help should be sought for persistent warnings or complex repairs.

| Symptoms | Possible Causes |

|---|---|

| Dashboard warning lights present | Low oil pressure |

| Engine overheating | Hydraulic system leaks |

| Unusual sounds from the engine | Electrical issues |

| Loss of power | Faulty sensors |

Problem Description

The Case Dozer is a trusted machine in construction and earthmoving applications, known for its efficiency and durability. However, like any heavy machinery, it can encounter problems that trigger warning lights. These lights serve as critical indicators of potential issues that could affect performance or even lead to breakdowns if not addressed promptly. Ignoring these warnings can result in increased repair costs, extended downtime, and compromised safety.

Common Symptoms

Operators should be vigilant and observant for various symptoms that may accompany warning lights on Case dozers. Recognizing these can help in diagnosing the problem early:

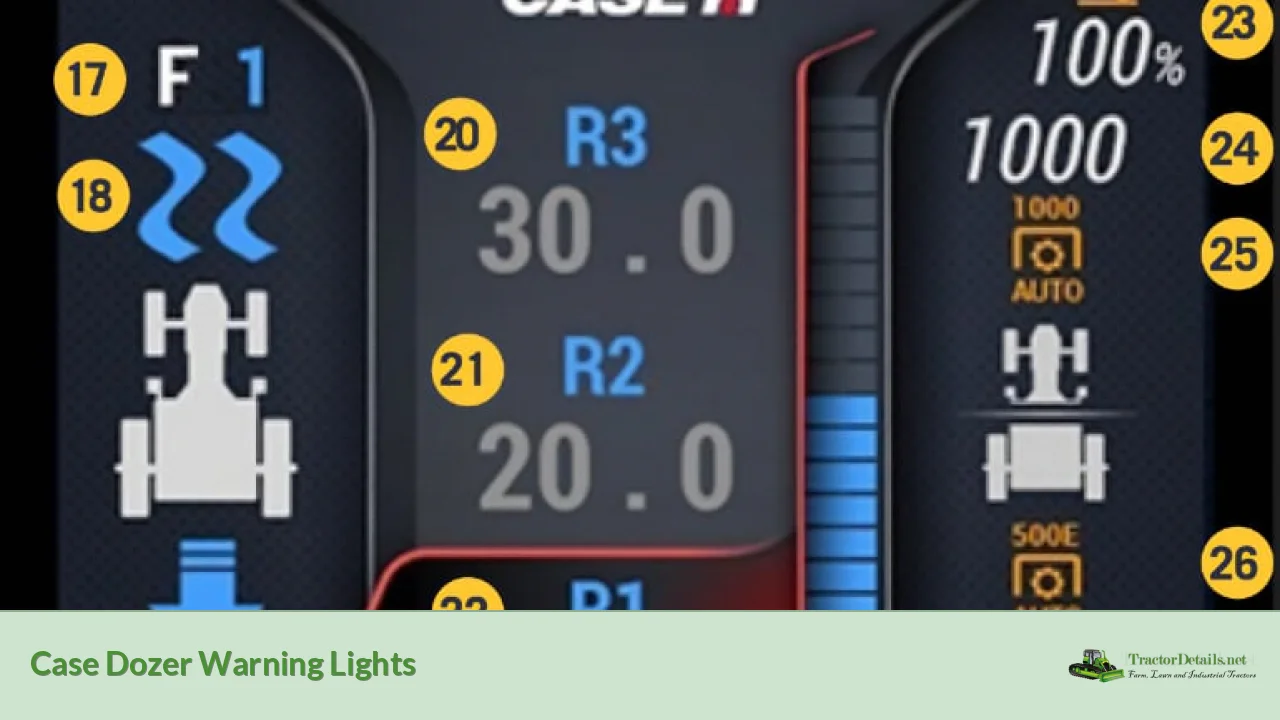

- Dashboard Warning Lights: Illuminated warning indicators corresponding to various subsystems (e.g., engine, hydraulics).

- Overheating Engine: Increased engine temperatures well beyond operational limits.

- Performance Issues: Slow response times, sluggish performance, or complete power loss.

- Unusual Noises: Grinding, rattling, or hissing sounds, suggesting mechanical issues.

- Fluid Leaks: Pools of oil or hydraulic fluid under the dozer, indicating a leak.

Possible Causes

Understanding the underlying causes of warning lights can assist in faster troubleshooting and repairs. Some common causes are:

- Low Oil Pressure: Could be due to low oil levels, a failing oil pump, or oil leaks.

- Hydraulic Issues: A leaking hose or low hydraulic fluid levels can cause warning signs to trip.

- Electrical Malfunctions: Faulty sensors or wiring can falsely trigger warning lights.

- Engine Troubles: Issues like overheating, irregular fuel supply, or wear and tear can cause alerts.

- Faulty Sensors: Sometimes sensors themselves can fail, leading to erroneous warning lights.

Diagnosis Steps

To effectively diagnose issues indicated by warning lights on a Case Dozer, follow these structured steps:

- Check the Dashboard: Immediately observe which warning lights are illuminated and consult the owner’s manual.

- Inspect Fluid Levels: Verify oil, coolant, and hydraulic fluid levels.

- Look for Leaks: Examine the machine for any visible fluid leaks that could indicate a major issue.

- Listen for Unusual Noises: While operating the machine, pay attention to any strange sounds emanating from the engine or hydraulic system.

- Run Diagnostic Tests: Utilize any onboard diagnostic systems that may offer fault codes or additional information about the dozer’s performance.

Troubleshooting and Repair Procedures

Once the diagnostics are conducted, operators can proceed with troubleshooting. Here are some recommended practices:

-

For Low Oil Pressure:

- Check oil levels; add oil if low.

- Inspect the oil pump and replace it if necessary.

- Look for leaks around the oil lines and seals.

-

For Hydraulic System Issues:

- Inspect hydraulic fluid levels and refill if necessary.

- Examine hoses for leaks or significant wear.

- Replace damaged hoses and couplings as needed.

-

For Engine Problems:

- Check coolant levels and ensure the cooling system is functioning correctly.

- Inspect fuel lines and filters for clogs or leaks that could affect performance.

- Consult error codes using diagnostic tools to identify specific engine malfunctions.

-

For Electrical Failures:

- Inspect wiring harnesses and connectors for signs of wear or corrosion.

- Test sensor operation to ensure they are functioning correctly.

- Replace faulty sensors based on their readings.

Estimated Repair Costs

Repair costs for Case Dozers can vary significantly based on the issue’s complexity. Here’s a general idea of what to expect:

- Low Oil Pressure Repairs: $150 – $500, depending on the cause (pump replacement, oil change).

- Hydraulic System Repairs: $300 – $1,200, depending on hose replacements or complete system rehabilitation.

- Engine Repairs: $500 – $3,000, depending on the complexity, whether it’s overheating issues, gaskets, or deeper diagnostics.

- Electrical Repairs: $200 – $1,500, depending on the extent of wiring or sensor replacements.

Prevention Tips

Preventive maintenance is an effective strategy to reduce the likelihood of warning light issues. Consider the following practices:

- Regular Maintenance: Stick to a maintenance schedule that includes oil changes, filters, and fluid top-offs.

- Daily Inspections: Conduct daily walkthroughs of the dozer, checking for leaks, unusual sounds, and fluid levels.

- Proper Training: Ensure operators are trained in identifying warning signs and understanding their implications.

- Diagnostic Checks: Periodically utilize onboard diagnostics to catch potential problems before they escalate.

When to Seek Professional Help

While many problems can be resolved with DIY effort, there are circumstances when professional help is warranted:

- Persistent Warning Lights: If warning lights remain on despite troubleshooting.

- Complex Mechanical Failures: Issues that require specialized tools or extensive experience should be handled by professionals.

- Safety Concerns: Any situation where operating the dozer leads to potential safety hazards.

Conclusion

Case Dozer warning lights serve as vital indicators that can prevent mechanical failures and preserve the safety of operators. Awareness of symptoms, understanding potential causes, and following proper diagnostic and repair protocols can save time and money. Regular maintenance and prompt attention to warning signals are crucial for optimizing your dozer’s performance. By being proactive in monitoring and maintaining your machinery, you can extend its operational life and ensure reliability on the job site. If unresolved issues persist, don’t hesitate to reach out for professional assistance to keep your equipment in top shape.It looks like your message got cut off. Could you please provide more context or let me know what you’d like to continue discussing?